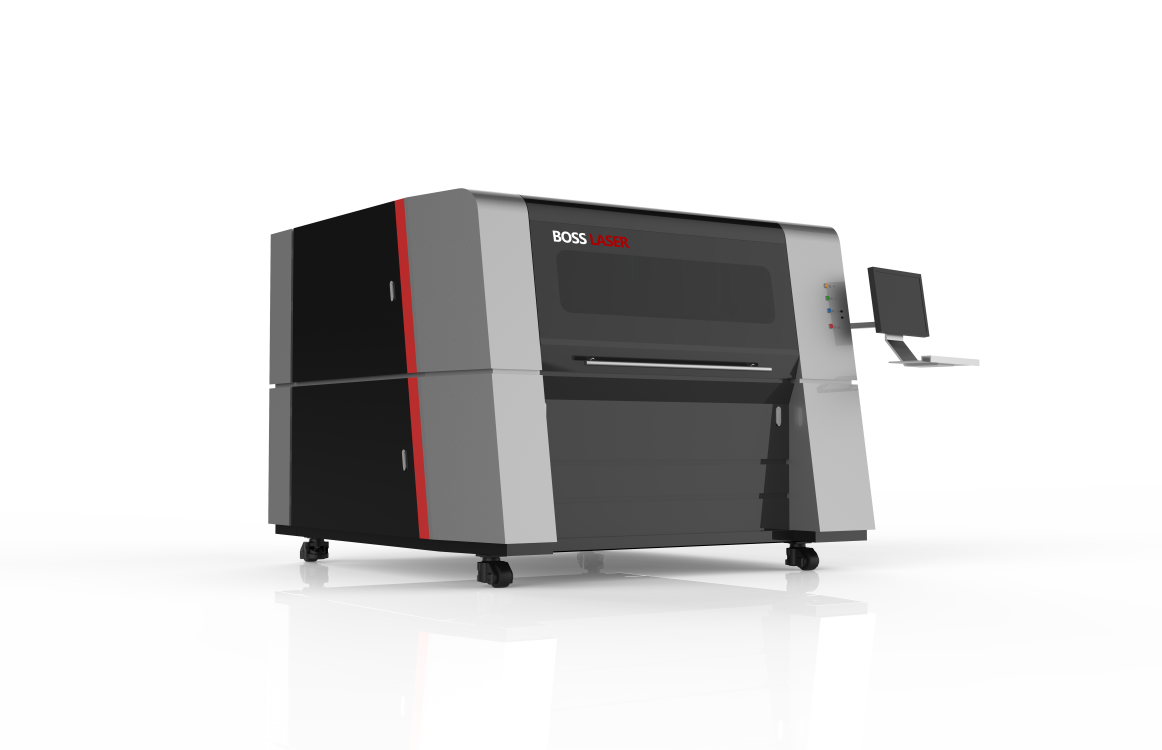

FCAccuCUT

-

CUT/ENGRAVE/MARK

-

70W CO2 LASER TUBE

-

STARTING AT $69,997

CUT/ENGRAVE/MARK

70W CO2 LASER TUBE

STARTING AT $69,997

The FC Accu-CUT enclosed laser cutter offers superior sheet metal cutting accuracy. An enclosed 4'x4' fiber machine with USA made fiber power the Accu-CUT offers greater precision, power, and speed than all its predecessors. Laser cut stainless, carbon steel, aluminum, brass, titanium, and other metal alloys.

My wife and I had a fantastic demo with Frank and Ken. Ken offered so much more than just demonstrating the Laser. There are product displays that he took time explaining how the product was engraved.

Read All Reviews +IPG-500W Fiber Power:

The ACCU-Cut goes the extra mile with a precision ball screw with support from dual HiWinn rail guides for the X, Y, and Z axis'. The dual Y-axis is ball screw driven on both sides then further supported by 20mm HiWinn Dual Rails and bearings. All of which are critical for maintaining max precision kerf cutting especially during high speed processing.

Accu-CUTTM is equipped with premium components geared for Extreme Precision and position accuracy (±0.008mm). All 3 axes are ball screw driven with dual HIWINN rails and bearing blocks for maximum precision cutting.

Y axis dual drive

X single drive

Yaskawa's SGM7J servo was designed to maximize responsiveness in applications where precise load matching is of critical importance. This family of medium inertia rotary, brushless servo motors was created with low capacity applications in mind, yet can respond with rated speeds to 3000 rpm and torque ratings up to 2.39 N-m (21 in-lb) when an application requires it. 24-bit encoder resolution maintains industry-leading positional accuracy in any operating condition.

Manufactured to aerospace standards to 6061 T6 - hardened aluminum alloy. T6 temper 6061 aluminum is treated to provide the maximum precipitation hardening (therefore yielding maxium strength). Aviation aluminum has many advantages beyond strength including light weight, corrosion resistant, low density, all of which contribute ot improved processing speeds.

Swiss made fiber laser head suitable for medium and high power fiber lasers in industrial applications. Includes a new dust-proof design. The result is that it eliminates collimation lens contamination. Also, a top protective window was added to the collimation assembly as well as the bottom protective window structure is also fully upgraded with protection. This double protection design enhances the user experience by practically eliminating any lens contamination risk.

Head Features:

Machine mounted and adjustable Monitor connected to Windows 10 PC. Includes CYP-CUT laser interface pre-installed.

Designed for laser cutting CypCUT is a popular and robust software for industrial fiber laser systems. It includes control card, breakout board with a wireless remote along with a free standing capacitive height adjustor. On the VIDEOS tab you can view the nesting utility.

NOTE: All FC series laser purchases include a minimum of 2 days install and training of which operators will be able to understand CypCUT functionality.

As we continue to design, engineer, and assemble our laser systems here at Boss we have expanded our facilities to 43,000 sq. ft. We continue to build in-house as well. We strive to improve our quality output by upholding our IS0-9001:2015 certifcation. We are also members of BBB, D&B, System for Award Management (SAM), and Laser Institute of America (LIA). See a laser Live! Come and visit us in Sanford, FL just 20 min North of Orlando.

Get producing quickly and efficiently! Boss' fiber laser cutters include Two (2) Days of On-Site Installation & Training that covers machine safety, set-up, basic software functions, and if time permits new job set up.

Our dual temperature water chiller provides 4200 watts of cooling capacity. Designed for cooling 1000W fiber lasers they are include both a dual circulating refrigeration and dual temperature control systems.

Removable SawTooth Blade Cutting Platform and material clamps for sheet metal processing.

ISO 9001 is the International Standard for a quality management system (“QMS”). In order for our company to be third party certified to the ISO 9001 standard, we had to follow the requirements set forth within the Standard. ISO 9001 evaluates whether our QMS is first appropriate and effective, and then forces us to identify and implement improvements.

In short the standard demonstrates our ability to consistently provide products and services that meet customer and regulatory requirements and to demonstrate continuous improvement. The current version is ISO 9001:2015, which was published in September of 2015 (thus the: 2015).

Our In-House Tech Support team is here to serve and support from the day you receive your BOSS Laser and for as long as you own the machine. Our tech support utilizes video, help manuals, phone, email, remote support via. Team Viewer, FaceTime, and even on-site support if necessary. Need on-site installation and training for your team? Give us a call we're here to help!

Having supported thousands of businesses, hobbyists, educational, military, and Government institutions we know and understand how critical it is to be able to deliver competant and timely support. Quality support begins with warehousing ALL parts to the machine you purchase - in our facilites. That way if you have an issue with your laser cutter we can not only diagnose the problem we can also ship you the part you need same or next day. This way you experience minimal down time.

Boss' fiber laser power warranty is two (2) years covers all parts including the fiber laser source. Have questions? We're here to help: 407-878-0880.

The FC-AccuCUT comes standard with the X-Series 70W Laser Tube which can be upgraded to 105W or 150W.

Learn More >The FC-AccuCUT comes standard with the X-Series 70W Laser Tube which can be upgraded to 105W or 150W.

Learn More >FC Series

X=51.2", Y=51.2", Z=3" (1,300 x 1,300mm)

IPG CW 500W, 700W, 1KW, or 2KW

Single phase 220V

Call for this info

CypCUT Plane Cutting Software

86"W x 85"L x 64"H

AC Servo Motors with AC Servo Driver

Laser head up/down 3"

Steel Tooth cutting platform

Air exhaust fans with venting pipe

3,900 lbs.

2 Years (includes parts & laser power)

Class 4 laser

test1

test2

test1

test2

BOSS Laser has been exceptional in providing customer support. They have on numerous occasions helped our school solve a problem in regards to our laser and have shipped materials in a very timely manner. I would recommend BOSS Laser to those interested in purchasing a laser machine.

Read more >We are at the start of our investigation into what is the right solution for our applications and my recent visit to BOSS Laser was amazing. The knowledge and passion of the team was clear and my visit not only answered all of my questions, it also helped me better understand ways to make the most of a laser.

Read more >My wife and I had a fantastic demo with Frank and Ken. Ken offered so much more than just demonstrating the Laser. There are product displays that he took time explaining how the product was engraved. We went there thinking about purchasing the entry level machine and left purchasing a larger unit. The facility, the time Ken spent with us and the help Frank gave us was just impressive and most helpful. We buy a lot of equipment and could not compare any of our other vendors to what we experienced with Boss Laser but more with the demo Ken gave us. Frank was very helpful, no pressure just there to give us the facts and let us make our decision. Wonderful experience and we look forward to our new laser from Boss!

Read more >Whenever I have had a problem or difficulty, I always contact them and with the information they give me I can solve any problem I have had. I feel very supported.

Read more >Excellent demo with BOSS laser, great team that makes a great product. They walked through numerous product samples I had and answered all questions. I look forward to doing business with them.

Read more >We are at the start of our investigation into what is the right solution for our applications and my recent visit to BOSS Laser was amazing. The knowledge and passion of the team was clear and my visit not only answered all of my questions, it also helped me better understand ways to make the most of a laser.

Read more >BOSS Laser has been exceptional in providing customer support. They have on numerous occasions helped our school solve a problem in regards to our laser and have shipped materials in a very timely manner. I would recommend BOSS Laser to those interested in purchasing a laser machine.

Read more >We are at the start of our investigation into what is the right solution for our applications and my recent visit to BOSS Laser was amazing. The knowledge and passion of the team was clear and my visit not only answered all of my questions, it also helped me better understand ways to make the most of a laser.

Read more >My wife and I had a fantastic demo with Frank and Ken. Ken offered so much more than just demonstrating the Laser. There are product displays that he took time explaining how the product was engraved. We went there thinking about purchasing the entry level machine and left purchasing a larger unit. The facility, the time Ken spent with us and the help Frank gave us was just impressive and most helpful. We buy a lot of equipment and could not compare any of our other vendors to what we experienced with Boss Laser but more with the demo Ken gave us. Frank was very helpful, no pressure just there to give us the facts and let us make our decision. Wonderful experience and we look forward to our new laser from Boss!

Read more >Whenever I have had a problem or difficulty, I always contact them and with the information they give me I can solve any problem I have had. I feel very supported.

Read more >Excellent demo with BOSS laser, great team that makes a great product. They walked through numerous product samples I had and answered all questions. I look forward to doing business with them.

Read more >We are at the start of our investigation into what is the right solution for our applications and my recent visit to BOSS Laser was amazing. The knowledge and passion of the team was clear and my visit not only answered all of my questions, it also helped me better understand ways to make the most of a laser.

Read more >BOSS Laser has been exceptional in providing customer support. They have on numerous occasions helped our school solve a problem in regards to our laser and have shipped materials in a very timely manner. I would recommend BOSS Laser to those interested in purchasing a laser machine.

Read more >We are at the start of our investigation into what is the right solution for our applications and my recent visit to BOSS Laser was amazing. The knowledge and passion of the team was clear and my visit not only answered all of my questions, it also helped me better understand ways to make the most of a laser.

Read more >My wife and I had a fantastic demo with Frank and Ken. Ken offered so much more than just demonstrating the Laser. There are product displays that he took time explaining how the product was engraved. We went there thinking about purchasing the entry level machine and left purchasing a larger unit. The facility, the time Ken spent with us and the help Frank gave us was just impressive and most helpful. We buy a lot of equipment and could not compare any of our other vendors to what we experienced with Boss Laser but more with the demo Ken gave us. Frank was very helpful, no pressure just there to give us the facts and let us make our decision. Wonderful experience and we look forward to our new laser from Boss!

Read more >Whenever I have had a problem or difficulty, I always contact them and with the information they give me I can solve any problem I have had. I feel very supported.

Read more >Excellent demo with BOSS laser, great team that makes a great product. They walked through numerous product samples I had and answered all questions. I look forward to doing business with them.

Read more >We are at the start of our investigation into what is the right solution for our applications and my recent visit to BOSS Laser was amazing. The knowledge and passion of the team was clear and my visit not only answered all of my questions, it also helped me better understand ways to make the most of a laser.

Read more >